We stand for the transfer of knowledge from science into practice

The ChondroFiller® products have been developed in a close cooperation between our team and scientists, doctors and researchers from the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart. This research and development work has been turned by meidrix biomedicals into products for orthopaedic practice. And to bring things full loop, it goes without saying that the use of ChondroFiller® has been independently tested both in scientific and clinical studies.

Research and development

We are extremely happy to share our decades of experience in biomaterials and regenerative medicine with cooperation partners from clinical, university and industry sectors for innovative research and development projects in a far-reaching network.

An overview of scientific studies can be found below:

2016 | Stretching human mesenchymal stromal cells on stiffness-customized collagen type I generates a smooth muscle marker profile without growth factor addition.

Rothdiener, M., Hegemann, M., Uynuk-Ool, T., Walters, B., Papugy, P., Nguyen, P., Claus, V., Seeger, T., Stoeckle, U., Boehme, K. A., Aicher, W. K., Stegemann, J. P., Hart, M. L., Kurz, B., Klein, G., & Rolauffs, B. (2016). Stretching human mesenchymal stromal cells on stiffness-customized collagen type I generates a smooth muscle marker profile without growth factor addition. Scientific reports, 6, 35840.

2017 | Mechanobiological processes of tissue engineered cartilage replacement materials.

Nachtsheim, J., Markert, B. and Stoffel, M. (2017), Mechanobiological processes of tissue engineered cartilage replacement materials. Proc. Appl. Math. Mech., 17: 211-212.

2017 | The geometrical shape of mesenchymal stromal cells measured by quantitative shape descriptors is determined by the stiffness of the biomaterial and by cyclic tensile forces.

Uynuk-Ool, T., Rothdiener, M., Walters, B., Hegemann, M., Palm, J., Nguyen, P., Seeger, T., Stöckle, U., Stegemann, J. P., Aicher, W. K., Kurz, B., Hart, M. L., Klein, G., & Rolauffs, B. (2017). The geometrical shape of mesenchymal stromal cells measured by quantitative shape descriptors is determined by the stiffness of the biomaterial and by cyclic tensile forces. Journal of tissue engineering and regenerative medicine, 11(12), 3508–3522.

2017 | Engineering the geometrical shape of mesenchymal stromal cells through defined cyclic stretch regimens.

Walters, B., Uynuk-Ool, T., Rothdiener, M., Palm, J., Hart, M. L., Stegemann, J. P., & Rolauffs, B. (2017). Engineering the geometrical shape of mesenchymal stromal cells through defined cyclic stretch regimens. Scientific reports, 7(1), 6640.

2018 | Chondrocyte migration in an acellular tissue‐engineered cartilage substitute.

Nachtsheim, J., Dursun, G., Markert, B. and Stoffel, M. (2018), Chondrocyte migration in an acellular tissue‐engineered cartilage substitute. Proc. Appl. Math. Mech., 18: e201800425.

2019 | Experimental Study on Cell-free Approach for Articular Cartilage Treatment, Current Directions in Biomedical Engineering.

Dursun, G., Markert, B., & Stoffel, M. (2019). Experimental Study on Cell-free Approach for Articular Cartilage Treatment, Current Directions in Biomedical Engineering, 5(1), 171-174.

2019 | Trefoil Factor 3 (TFF3) Is Involved in Cell Migration for Skeletal Repair.

Krüger, K., Schmid, S., Paulsen, F., Ignatius, A., Klinger, P., Hotfiel, T., Swoboda, B., & Gelse, K. (2019). Trefoil Factor 3 (TFF3) Is Involved in Cell Migration for Skeletal Repair. International journal of molecular sciences, 20(17), 4277.

2019 | Chondrocyte colonisation of a tissue-engineered cartilage substitute under a mechanical stimulus.

Chondrocyte colonisation of a tissue-engineered cartilage substitute under a mechanical stimulus.

2020 | Compression Bioreactor-Based Mechanical Loading Induces Mobilization of Human Bone Marrow-Derived Mesenchymal Stromal Cells into Collagen Scaffolds In Vitro

Medical Faculty Mannheim, Heidelberg University, 68167 Mannheim, Germany;

Carolina.Gamez@medma.uni-heidelberg.de (C.G.); Baerbel.Schneider6@gmx.de (B.S.-W.);

as.work@aikq.net (A.S.)

2020 | Complex mechanical behavior of human articular cartilage and hydrogels for cartilage repair

ProMatLeben – joint project

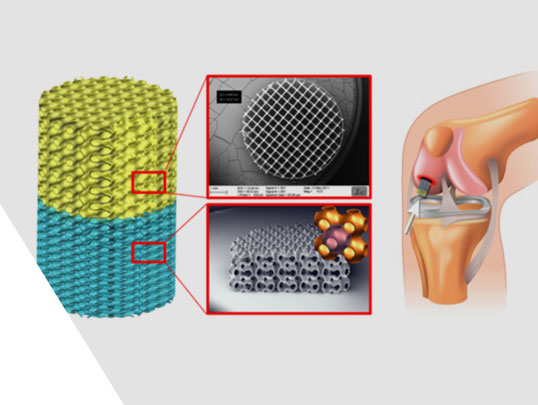

Research into an industrial laser-based nano 3D printing technique for hierarchically structured cartilage bone implants on a polymer basis (Poly-IMPLANT-Print)

- Mathys Orthopädie GmbH: research of implant-specific surgical instruments

- IBA Heiligenstadt e.V.: research of photopolymers and 3D frame structures

- Multiphoton Optics GmbH: research of a two-photon polymerisation process for production of the implant

- meidrix biomedicals GmbH: research of collagen functionalisation of the implants

- University of Giessen: research of osteogenic differentiation capacity in the implant

The goal of the joint project Poly-IMPLANT-Print is to develop biphasic scaffold structures on the basis of biocompatible polymers for optimum treatment of bone-cartilage defects: the scaffold structures should have suitable cartilage and bone-specific geometric, biomechanical and biochemical properties. Here, the structures of the cartilage and bone phases can differ. The 2PP technology as a variable 3D printing technology in connection with an automated production process represents the key for targeted microstructuring of a 3D scaffold construction in combination with adjustment of material stiffness, bioactivity of the scaffold surfaces, simulation of the extracellular matrix (ECM) and degradation speed.

Facts about the project and further links:

- Duration: 01-May-2019 – 30-Apr-2022

- Project link: www.promatleben.de/de/projekte/projekte-alphabetisch/poly-implant-druck

- ProMatLeben programme: www.promatleben.de of BMBF www.bmbf.de

- Lead project partner: VDI Projekt GmbH www.vditz.de

- Sponsored by: German Federal Ministry of Education and Research (BMBF) www.bmbf.de

ZIM-Kooperationsprojekt

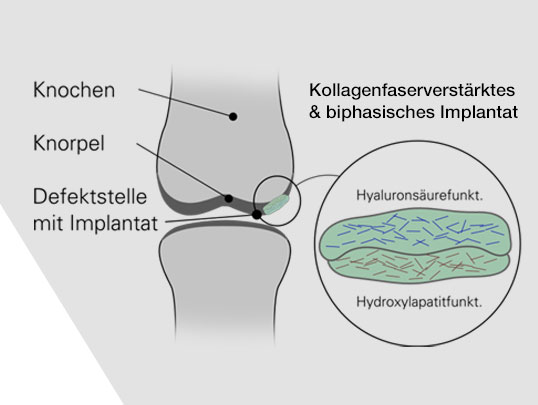

Development of a collagen fibre-reinforced and biphasic implant for cartilage regeneration

meidrix biomedicals GmbH and the Institute of Textile Machinery and High Performance Material Technology (ITM) at Dresden University of Technology are partners in a cooperation project as part of ZIM, the innovation programme for small and medium-sized enterprises run by the Germany Federal Ministry for Economic Affairs and Energy.

The goal of the ZIM cooperation project is to develop innovative functional and biphasic collagen fibre implants for joint cartilage regeneration.

The objective of the project is the development of a cell-free and absorbable implant reinforced with functionalised collagen fibres for cartilage regeneration in the knee. This biphasic implant with a layered structure is to consist of two parts: one part facing the bone and one part facing the cartilage. Both parts consist of a collagen gel reinforced with collagen fibres, whereby the wet-spun collagen fibres are functionalised in different ways depending on the layer. Both the functionalisation and the biphasic layout of the implant are strictly based on the layout of natural cartilage and the boundary surface between bone and cartilage.

The biphasic structuring of the implant is intended to achieve a significant improvement of cartilage regeneration, while the fibre reinforcement achieves higher strength and resilience in comparison to previously available products.

Facts about the project and further links:

- Duration: 01-Mar-2019 – 28-Feb-2021

- Project partners: Dresden University of Technology, Institute of Textile Machinery and High Performance Material Technology (ITM), contact person: Dr.-Ing. Dilbar Aibibu, Robert Tonndorf

- Programme: ZIM (German state innovation programme for small and medium-sized enterprises) www.zim.de

- Lead project partner: AiF Projekt GmbH www.aif-projekt-gmbh.de

- Sponsored by: German Federal Ministry for Economic Affairs and Energy (BMWi) www.bmwi.de

Further partners

Fraunhofer Institut

www.igb.fraunhofer.de

BBF Sterilisationsservice GmbH

BioRegio STERN Management GmbH